Simply put, Ventilation can be defined as the intended admission of outdoor air into a space to maintain clean, healthy indoor environment. Finding a balance between inadequate and too much ventilation is crucial as the former can have a detrimental effect on both indoor climate and occupant while the latter can further increase a building's already high consumption of energy and CO2 production. This is where the concept of demand-controlled ventilation (DCV) comes into play.

What is DCV?

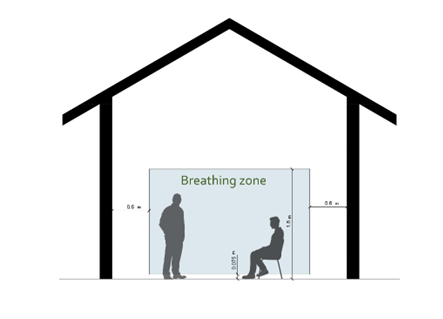

Demand control ventilation (DCV) is a ventilation control technique used in heating, ventilation, and air conditioning (HVAC) systems to optimize energy efficiency by adjustingwhile maintaining desired ventilation rates based on actual occupancy and air quality. In other words, outdoor air supply drops if a room is completely or partially vacant as compared to design occupancy while the system will automatically increase airflow as ocuupancy increases. According to ASHRAE 62.1, DCV is “Any means by which the breathing zone outdoor air (Vbz) can be varied to the occupied space or spaces based on the actual or estimated number of occupants, ventilation requirements of the occupied zone, or both.” Where, breathing zone is an inhabited area that is farther than 2 feet (600 mm) from walls or permanent air-conditioning equipment and between planes 3 and 72 inches (75 and 1800 millimetres) above the floor.

How DCV works?

Demand controlled ventilation (DCV) employs a feedback mechanism that automatically adjusts the volume of outdoor air delivered to a room according to changes in occupant count or indoor pollutant level. To determine the presence of people in a certain area, schedules, and various types of sensors, such as motion / vacancy sensors, infrared sensors and / or CO2 & VOC sensors, are employed. These components work together to deliver the best possible indoor comfort. Schedules use an already programmed method to estimate occupancy. For the most part, well designed schedules work correctly, but they cannot confirm if there are actually inhabitants in the area at the anticipated scheduled time. Motion and CO2 sensors are therefore essential in this situation. Motion sensors confirm occupants’ presence, whereas CO 2 sensors monitor the fraction of CO2 in the air. With the integration of DCV into BMS (Building Management System) or BAS (Building Automation Systems), ventilation rates and air quality may be controlled.

Where is DCV used?

Schools, universities, and hybrid working offices are just a few examples of the types of buildings where DCV can exhibit the best outcomes due to the most pronounced alterations in occupancy throughout the day. DCV is also advantageous in spaces with a variety of activity, such as mixed-use buildings.

Difference between VAV (Variable Air Volume) and DCV (Demand controlled ventilation) systems?

Usually, VAV system has the ability to adjust total supply airflow in a zone in order to maintain a desired temperature or quality of air over the course of operation. Mostly use of VAV without DCV is meant for temperature control, but on the other hand, DCV system allows sophisticated adjustments to be made based on a range of different criteria to maintain air quality in the space while reducing energy requirement. Although the initial investment is more for DCV system, the benefits over time include saving energy, easier building compliances and certifications, as well as increased productivity, health, and comfort.

What are the benefits of DCV?

• Maximising energy efficiency by saving energy and Utility costs while maintaining desired ventilation requiremnt.

• It can efficiently manages Indoor air quality (IAQ) and measure additional air quality parameters like volatile organic compounds (VOCs) or particulate matter (PM).

• DCV can be integrated into BMS and BAS systems.

• It serves as an excellent strategy to help with building certifications, for example, installing CO2 sensors in new or existing construction can help earn point under IEQ (Indoor Environmental Quality) criteria for LEED certification.

• DCV can be implemented in conjunction with a VAV system, which adjusts the airflow to different zones or spaces based on heating or cooling demands while maintaining the desired ventilation requirements.